What is GPF?

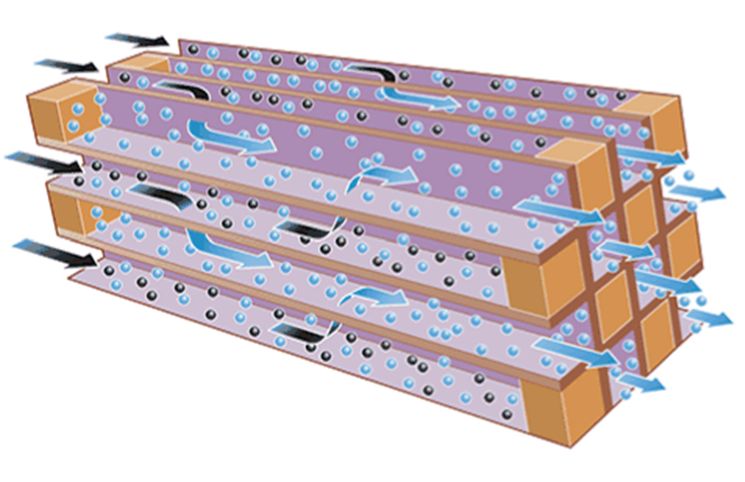

Automobile GPF refers to gasoline engine particle filter. GPF is a ceramic filter installed in the exhaust system of a gasoline engine. The shape is a cylinder, which is no different from the shape of traditional "three-way catalyst". The difference is the internal air flow channel. GPF is a wall-flow carrier. The inside of the carrier is parallel honeycomb pores. Only one of the adjacent two pores has an inlet open, and the other has only an outlet open. It can capture particulate emissions before they enter the atmosphere. The main function is to reduce particles, and through ECU control, the particles in the trap are oxidized and burned to achieve the purpose of regeneration.

GPF working mechanism

The filtering mechanism of GPF is basically the same as that of diesel engine DPF. Exhaust gas passes through the porous wall at a certain flow rate. This process is called "Wall-Flow”. The wall-flow particulate filter is composed of honeycomb ceramics with a certain pore density. By alternately blocking the honeycomb porous ceramic filter, the exhaust flow is forced to pass through the pore wall and the particles is captured and filtered through the four methods of diffusion, interception, gravity and inertia.

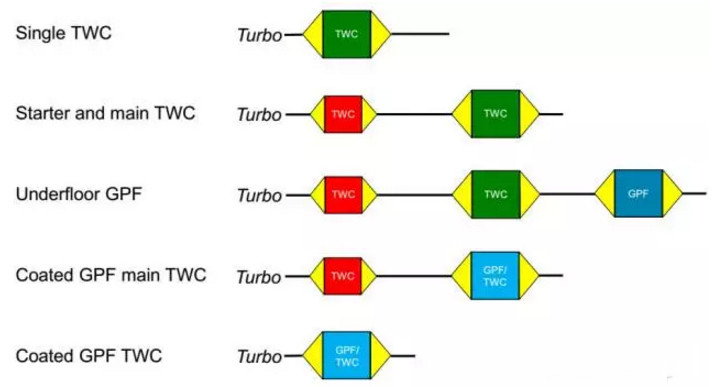

GPF layout plan

GPF is mainly arranged on the exhaust pipe of gasoline engine in three forms. One is integrated with TWC and installed closer to the exhaust manifold, that is a closed-coupled arrangement. The other is directly installed at the downstream position of the TWC, that is under-floor. And the other is the three-way catalyst coated on the GPF substrate to form a "four-way catalyst”.

GPF regeneration

After the particulate filter is used for a long time, soot particles accumulate on the microporous surface of the filter to form a PM layer and its storage volume will gradually decrease. The formation of the PM layer helps to improve the filtration efficiency, but there will be a throttling effect in the exhaust pipe, and the exhaust flow resistance becomes larger, which leads to an increase in fuel consumption and a decrease in engine output. At this time, it is necessary to replace or regenerate the GPF.

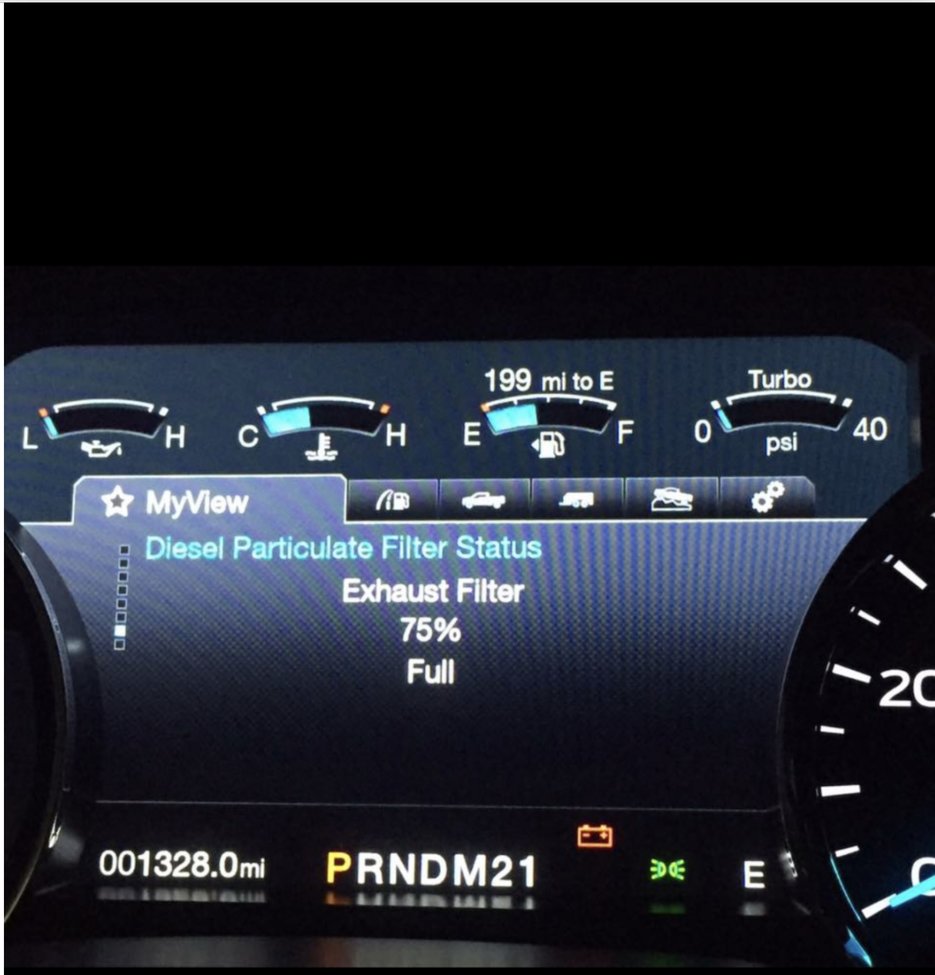

Since GPF collects particulate matter temporarily, it cannot be removed during daily short-distance driving. After a period of driving, the accumulated particulate matter in GPF gradually increases, causing the engine exhaust back pressure to rise and engine performance to decrease. To a certain extent, problems such as "acceleration weakness, fuel consumption soaring, automatic start-stop failure" and other problems occur, so it is necessary to regularly remove GPF particulate matter to restore exhaust back pressure.

Generally speaking, particulate matter is carbon, which can be converted into carbon dioxide by directly reacting with oxygen at high temperature. According to the instructions, when the GPF regeneration indicator light is on (green light), it indicates that PM has accumulated to a certain degree, and GPF needs Regeneration. At this time, you will be prompted to run high-speed conditions as much as possible (vehicle speed ≥60km/h). When the particulate matter is processed, the GPF indicator will turn off. When the GPF carbon load (particulate matter) reaches the maximum, it will cause problems such as increased fuel consumption, decreased power, idling jitter, gear shift frustration, etc. The GPF indicator is in a yellow state. At this time, driving is dangerous, and you need to force it through high idle speed. Let the exhaust gas temperature rise and burn off the carbon deposits.

The main considerations for the design and application of GPF are: filtration efficiency, exhaust back pressure, regeneration, use cost, durability, and impact on fuel economy. On the premise of ensuring high filtration efficiency to meet emission regulations, reducing exhaust back pressure as much as possible to reduce fuel consumption and CO2 emissions, ensuring periodic and reliable regeneration, increasing the service life of GPF, and reducing use costs have become the current major research hotspots .